From Rustic Cabin to Massive Stadium: The Spectacular Evolution of Timber Structures

Once used for small cabins and barns, timber now supports massive stadiums, skyscrapers, and research centers. This is the story of how wood became one of the most advanced structural materials on Earth.

How wood went from humble shelters to one of the most advanced structural materials on the planet

For centuries, wood meant simplicity:

log cabins, timber barns, mountain huts—structures defined by craftsmanship, warmth, and modest scale.

Today, that image has been completely flipped on its head.

Timber now supports colossal stadiums, soaring office towers, and ultra-modern research centers.

This isn’t nostalgia in lumber.

This is a full-scale structural revolution.

The evolution of timber construction is the story of:

- 🚀 Technological breakthroughs

- 🧪 Material science

- 🌍 Global sustainability demands

It’s the story of how one of humanity’s oldest building materials became one of the most advanced.

🌲 The Engine of Change: Engineered Wood

What made this leap possible?

Not magic.

Engineering.

Modern timber construction is powered by mass timber—a family of engineered wood products that completely rewrite what wood can do structurally:

- CLT (Cross-Laminated Timber)

- Glulam (Glued Laminated Timber)

- DLT (Dowel-Laminated Timber)

These are not your grandfather’s planks.

They are:

- ✅ Stronger than traditional solid timber

- ✅ Dimensionally stable

- ✅ Fire-predictable

- ✅ Precision-manufactured

💡 Why CLT Changed Everything

CLT is basically:

Plywood on steroids.

Multiple layers of lumber are stacked crosswise and bonded into massive panels that act as:

- Load-bearing walls

- Floor slabs

- Roof diaphragms

They span long distances with minimal deflection, rivaling concrete and steel in performance.

💪 Glulam: Timber That Learned to Fly

Glulam beams are built from multiple laminated boards and used for:

- Long-span roofs

- Curved arches

- Massive trusses

They carry loads once reserved only for steel, but with far less environmental cost.

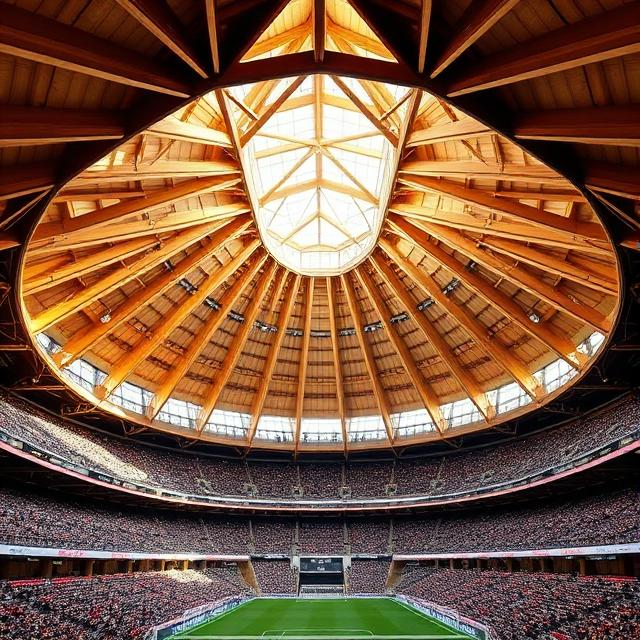

🏟️ Case Study: Idaho Central Credit Union Arena

Where Tradition Meets Monumental Scale

Few buildings display timber’s evolution better than the ICCU Arena in Idaho.

This 12,000-seat multipurpose venue is one of the largest all-timber performance arenas in the United States.

🔥 The Roof That Changed Perceptions

- 130-foot (40 m) timber span

- Supported by:

- Elegant king-post timber trusses

- Built from 854 individual glulam beams

- All timber sourced from:

- University-managed experimental forests

This is not symbolism.

It is closed-loop structural storytelling—from forest to landmark.

🌍 Environmental Impact

By using mass timber instead of steel and concrete, the arena avoided an estimated:

≈ 3,900 metric tons of embodied CO₂

That’s not a decoration choice.

That’s a carbon strategy.

The project earned:

- ✅ WoodWorks Wood Design Award

- ✅ ACEC Idaho Grand Award

Proof that timber isn’t a compromise.

It’s an upgrade.

🌍 Beyond the Arena: Timber Goes Global

ICCU Arena is not alone. Timber is everywhere—and climbing fast.

🏀 Victory Capital Performance Center – Texas

- 120,000 sq ft professional sports facility

- Built largely from mass timber

- Designed with biophilic principles

- Proven to support:

- Athlete recovery

- Mental performance

- Well-being

🏢 Katajanokan Laituri – Helsinki

- Mixed-use timber tower

- Office + hotel + public spaces

- Winner of:

- Large Workplace Project of the Year – Dezeen Awards 2025

🏙️ Icon’s Tall Wood Tower – Toronto

- 30-story residential timber tower

- North America’s tallest planned mass timber building

- Estimated GHG reduction:

≈ 3,300 metric tons of CO₂

Equivalent to removing 700 cars from the road for a full year.

🌿 Why Timber? The Triple Bottom Line

Timber doesn’t win because it’s trendy.

It wins because it dominates on three critical fronts:

⚡ 1. Speed

- Prefabricated timber elements arrive ready to assemble

- ICCU Arena’s massive roof trusses were erected in:

Just 5 weeks

Not months.

🌍 2. Carbon Sequestration

- 1 m³ of timber stores ≈ 1 ton of CO₂

- 1 ton of steel emits ≈ 1.9 tons of CO₂

Choosing timber isn’t neutral.

It’s actively regenerative.

🧠 3. Human Well-Being

Exposed timber interiors are scientifically proven to:

- Reduce stress

- Lower heart rates

- Improve focus and cognitive performance

This effect is known as:

Biophilia

In offices, schools, and hospitals, this means:

- Better productivity

- Faster healing

- Better learning

🧱 The Road Ahead: Codes, Fire & Digital Collaboration

Yes—challenges remain:

- Fire performance

- Acoustics

- Moisture detailing

- Building code updates

But modern timber uses charring-rate design:

- Thick timber chars on the outside

- The char layer insulates the structural core

- Load capacity remains predictable under fire

These are engineering problems, not material flaws.

🤝 What’s Driving Adoption Faster Than Ever

- Architects

- Structural engineers

- Fabricators

- Foresters

All now collaborate digitally using:

- Advanced CAD

- Parametric modeling

- Full BIM coordination before construction begins

Timber today is:

Designed digitally. Manufactured precisely. Assembled efficiently.

🏁 Conclusion: A Material Reborn

The journey from rustic cabin to massive stadium is not a trend.

It’s a paradigm shift.

Timber is no longer:

- The alternative material

- The quirky sustainable option

It is becoming:

The preferred structural system of the future

Strong.

Smart.

Sustainable.

And deeply human.

The future of construction isn’t just poured or welded.

It’s grown.

And built wisely within it. 🌲